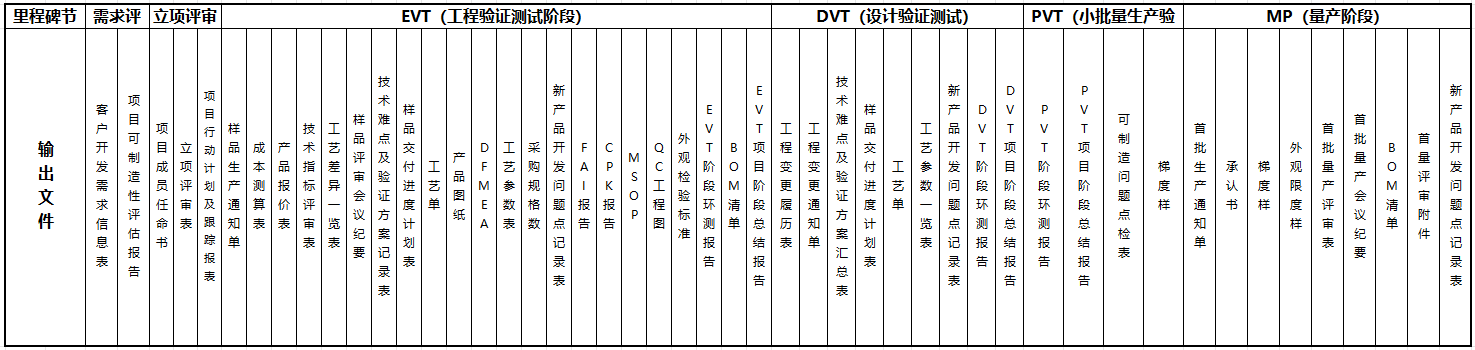

1. Unified mass production system from sample design to finished product quality assurance

Professional design team and efficient R & D capabilities, to provide various types of products, process development and related design solutions, with world-class precision machining technology to meet customer needs. From the whole process of sample design, material selection, cold processing, coating, screen printing, cutting and laminating, we have established a unified mass production system with short delivery time and quality assurance in all processing processes. Product development Import IPD process, shorten development cycle, improve product quality.

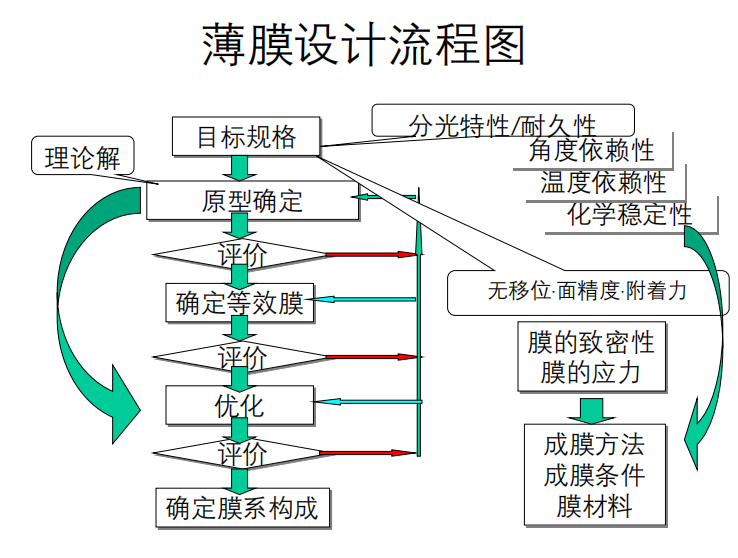

2. Coating technology

Using Japanese advanced coating equipment, we can provide a variety of single and multi-layer coatings for optical components in the ultraviolet (UV), visible light and infrared (IR) spectral range, offering IR/UV/BLUE/RED CUT, IR/UV PASS, BPF, STM and other film system designs.

3.1 Spinning coating technology

The use of Japan's advanced rotary coating equipment, combined with core coating technology, greatly improves the Flare problem during blue glass substrate imaging, thereby improving the overall use of lens modules.

3.2 Printing Technology

According to customer product needs to provide printing services of various styles, high precision, high performance, stable reliability, can be applied to various types of optical products.

3.3 Cutting Technology

High precision and high efficiency cutting technology, according to customer optical product requirements, processing of various sizes of lenses (square & round).

3.4 Bonding technology

Professional automatic filter components and flat optical glass bonding technology, to provide customers in various types of optical products adhesion services.

3.5 Cleaning Technology

According to different types of products, select the corresponding cleaning process (plasma cleaning, two-fluid cleaning, automatic cleaning and ultrasonic cleaning).

3.6 Test Technology

a. Internal measurement: including laser interferometer, spectrophotometer, turbidimeter, 3 dimensional, 3 point bending tester, to ensure product quality.

b. Environmental testing: Full range of tests for shock and vibration, temperature, humidity and other application requirements.